Projects

KAWASAKI Laser Welding System

KAWASAKI Laser Welding System for a customer in Abu Dhabi - UAE.

KAWASAKI 1,500 Bags/Hour Rice Palletizer

1,500 Bags/Hour Rice Palletizer for a Customer in Amman - Jordan.

Preventive Maintenance for 3x KAWASAKI CP180L Palletizing Robots

Successfully Performed Preventive Maintenance for 3x KAWASAKI CP180L Palletizing Robots for a Customer in Amman - Jordan.

KAWASAKI Arc-Welding System with 250KG Triple-Axis Positioner

KAWASAKI Arc-Welding System with 250Kg Triple-Axis Positioner for a customer in Abu Dhabi - UAE.

KAWASAKI Arc-Welding System for Cable Tray Bases

KAWASAKI Arc-Welding System for Cable Tray Manufacturer in Riyadh Saudi Arabia.

Preventive Maintenance for 2x FANUC LR Mate 200iD

Preventive Maintenance Performed for 2x FANUC LR Mate 200iD Robots.

Inspection & Troubleshooting for 2x KAWASAKI FA-010L Welding Robots

Onsite Inspection & Recovery Actions have been done for 2x KAWASAKI FA-010L Welding Robots.

Single Axis Positioner Manufacturing with 1,500Kg Payload for KAWASAKI BA006L Welding Robot

Inhouse Manufacturing of single axis positioner with 1,500Kg payload for Integration with KAWASAKI Arc-Welding Robot.

Dismantling 4x KAWASAKI RD080N Palletizing Lines

For relocation purpose without system's documentations availability, 4xKawasaki palletizing lines have been inspected, marked & dismantled.

Site Troubleshooting & Evaluation for 2xFS06N Old KAWASAKI Robots

Site Troubleshooting & Evaluation of 2xFS06N Old KAWASAKI Robots for a Customer in Jubail - Saudi Arabia.

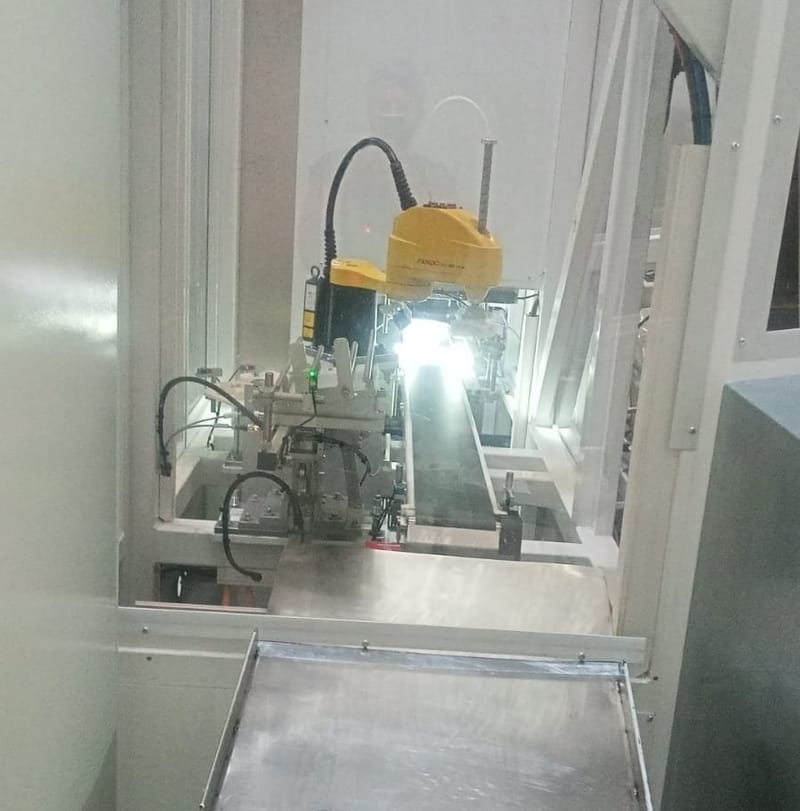

Replacing JT1 Motor & Gear for FANUC SR-3iA SCARA Robot

Complete Replacement of JT1 for FANUC SR-3iA SCARA Robot for a Customer in Khobar - Saudi Arabia.

For the 4th Year in Row, Preventive Maintenance Successfully Performed for 13x RD080N KAWASAKI Palletizing Robots.

Preventive Maintenance Successfully Performed for 13x KAWASAKI RD080N Palletizing Robots for a Customer in Riyadh - Saudi Arabia.