Projects

Dismantling , Shifting & Reinstalling KAWASAKI BA006L Arc-Welding Cell

In This Project , A complete arc-welding cell based on KAWASAKI BA006L robot dismantled , relocated to a new factory & reinstalled for a customer in Saida - Lebanon.

Adding 2xTurn-Table & 26m of Motorized Roller Conveyors for Existing Palletizing System

Addition of 2xTurn-Table & 26m of Conveyors to Existing Palletizer for a customer in Amman - Jordan

KAWASAKI Laser Welding Application

Laser Welding Robotic System for a Customer in Dubai - UAE.

Vacuum Gripper Design & Manufacturing

End of Arm Tool (EOAT) Designed & Manufactured for a System Integration Company in Dubai , UAE.

KAWASAKI Arc-Welding System with Positioner

KAWASAKI Arc-Welding System for a customer in Abu Dhabi - UAE.

Maintaining KAWASAKI BX200L Palletizing Robot

Successfully Performed Preventive Maintenance for KAWASAKI BX200L Robot for a Food Manufacturer in Jeddah , Saudi Arabia.

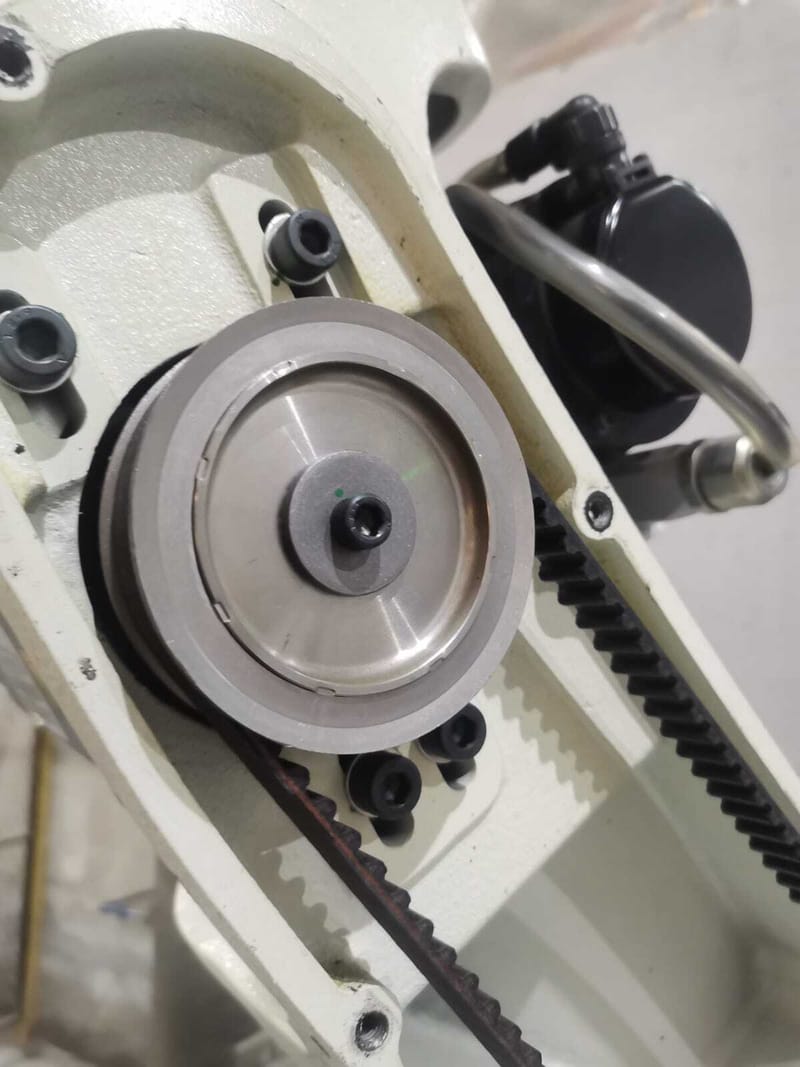

Motor Replacement for KAWASAKI CP500L Palletizing Robot

Successfully Performed Motor Replacement for KAWASAKI CP500L Robot for a Customer in Jeddah , Saudi Arabia.

Maintaining KAWASAKI BX200L Palletizing Robot

Successfully Performed Preventive Maintenance for KAWASAKI BX200L Robot for a Customer in Jazan , Saudi Arabia.

Maintaining KAWASAKI CP500L Palletizing Robot

Successfully Performed Preventive Maintenance for KAWASAKI CP500L Robot for a Customer in Jeddah , Saudi Arabia.

Maintaining 2x FANUC M710iC/50 Palletizing Robots

Successfully Performed Preventive Maintenance for 2x FANUC robots for a Customer in Jeddah , Saudi Arabia.

Maintaining KAWASAKI ZD-130S De-Palletizing Cell

Preventive Maintenance Performed for KAWASAKI ZD-130S Robot Arm for a Customer in Jeddah , Saudi Arabia

KAWASAKI Arc-Welding System with 8m Rail

KAWASAKI Arc-Welding System for Tubes Welding for a customer in Abu Dhabi - UAE.